The first thing to know about reloading, or handloading, isn’t what manufacturer to choose for a particular component.

It’s safety, safety, safety.

Focus.

Perhaps no activity you’ll pursue requires the focus and attention to detail that reloading does. You’ll need 100% of both time and space devoted to your concentration on the task at hand. No TV. No children. No distractions of any kind.

Secure Storage.

Secure Storage.

Would you store gasoline next to a wood stove? Of course, you wouldn’t. Your primers and powders need to be stored in a secured place—away from children and the general public—as well as far from heat or open flames.

The Manufacturer Knows Best (But Application is Up to You).

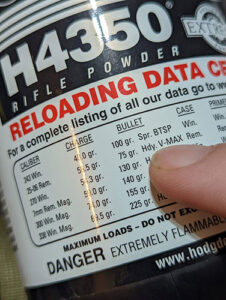

No matter how much you think you know about a certain product, the manufacturer knows more. Not only has the manufacturer spent countless thousands of hours—and dollars—in testing, developing, trial and error. They also have a lot of skin in the game to make sure their product functions as intended. Therefore, the manufacturer should be the final authority on reloading. They’re the first and last source of useful and pertinent data when any questions arise, or when you want to follow proper tolerances and procedures. When a manufacturer provides specific instructions or data, obey it. Many times, you won’t be able to find exact load data; reference items that are as similar as possible, and continue to err on the extremely conservative side.

Instructions Matter.

Reloading isn’t extremely complicated, but knowing the steps and following them in order is of utmost importance. Memorizing the steps of reloading from any reputable reloading manual will benefit you for as long as you choose to pursue the practice. A good manual can prepare you for safe, efficient reloading, as well as help you steer clear of potential problems in advance.

Protective Gear.

You’re literally dealing with explosive compounds when you’re reloading. As such, you’re going to want to wear protective gear. Proper eyewear can protect you from both accidental detonation, and any powders or residue that may be present when you’re working. As with all things involved with reloading, don’t take a chance. Wear the gear.

Measure Twice, Cut Once.

It costs nothing but time to measure your powder or your case length again. Once the cartridge is completed, you can no longer measure the powder sealed in the case. If you are ever unsure of a measurement or lose track of anything, stop and do it again. Keep your loading manual open and reference the data as much as you need.

Keep Things Organized And Clean.

Keep Things Organized And Clean.

Your work bench should be a pristine thing of beauty. It should be free of excess powder or primer. Sweep it up with a whisk broom—a vacuum creates a volume of dust. Don’t use your work area for other items like oily machine parts or other things that can affect the sterile, dedicated purpose of your reloading station. And, clean your area frequently. Certainly, it should be cleaned after each and every reloading session—all supplies & tools should be stored immediately after you’re done reloading for a single session. Even if you plan on getting back to reloading in a day or two.

Don’t Push The Maximum. (Or The Minimum.)

Yes, you should rely heavily on published data regarding the minimum and maximum loads when using powder. However, pushing the max right off the bat is a mistake until you’ve tested your reloads. Back the maximum off by 10 or 15 percent, then slowly climb your way up. That’ll prevent damage to yourself—and your firearm. Always be vigilant in looking for characteristics of excessive pressure as you approach the maximum. And, don’t forget that falling below the minimum suggested load isn’t a good thing, either. You want to build great ammo, not a pipe bomb. There are numerous ways to check for overpressure—so use them. On the opposite end of the spectrum, forgetting to fill a case with powder, or underfilling a case can create a squib load—a weak, underpowered load that pushes a bullet only partially down the barrel, creating a dangerous obstruction.

One Thing At A Time.

Even if you intend to reload several different calibers, or use different components along the way, you should only reload one setup at a time. That means one powder, one primer, one bullet, and one case. Don’t even take the remotest of chances of inadvertently using the wrong component. The wrong cartridge or powder can have disastrous results. And, when you’re finished with a reloading setup, put EVERYTHING away before you start the next.

Know What You’re Working With.

Know What You’re Working With.

If you aren’t 100% totally and irrefutably certain as to the brand and type of component you’re using, do not use it. Mysteries are fine for Agatha Christie, but for reloaders, it’s a defeinitive non-starter. Whether you discover some random primers in the bottom of a tool box, or happen upon some leftover powder you SWEAR you recall being a certain type, just remember that you’re creating an explosive device and trash those orphaned mystery items. And it’s also a helpful reminder to CLEARLY label all items or, better still, store them in their original manufacturer’s packaging. Lables like “twice-fired 308 brass, Winchester, de-primed” can go a long way to staying safe, and building more consistent ammunition.

Use Available Data, And Your Own.

Use Available Data, And Your Own.

Whether it’s the internet, or the manufacturer’s data you find printed in an up-to-date form, try to follow the suggested data out there on combinations of components that will deliver the best outcome with the least risk. Reloading forums can be a good source of information, but are not as trustworthy as the manufacturer’s recommendation. USE THIS DATA FOR REFERENCE ONLY. This information can be helpful to source different combinations of components, or to understand approximate measurements, but no one else has your exact same rifle, the exact same batch of components, and your exact same tools. NEVER simply use a reloading recipe you found on the internet. If it generally makes sense for your set-up, then back it off and work up to it.

Keep Good Records.

Keep Good Records.

Keeping copious records of your reloading increments and component brands will pay big dividends when you find a combination that enhances the performance you require from your firearm. Naturally, knowing what ISN’T as effective will aid your efforts as well. Not only should you track recipes and components, but it can be helpful to view your notes like a diary of record of work. Don’t just write down the combination you liked…track everything you tried and why you didn’t pursue it further (inaccurate, low velocity, pressure signs, ran out of powder, etc.) This may help you troubleshoot, make safe substitutions, or build up helpful knowledge for future load development.

Don’t Skimp On Tools.

Don’t Skimp On Tools.

How many times have you bought something on the cheap and regretted it? If you’re reloading, taking the less-than-high-quality way out isn’t an option. While it might seem like a good idea at the time, cheap products will give a cheap performance. You’re going to want quality tools to produce a quality, reliable result. And you’ll want items designed specifically for reloading. (So, you’ll be leaving that kitchen scale in the kitchen where it belongs and getting a reloading scale.)

Get The Lead Out.

Lead isn’t the friendliest substance on earth to the human body. And, you’ll find lead in most primers and most bullets. So, you’re going to be exposed to lead when handling reloading items (just as you will when cleaning or firing your firearm). To limit your extended contact, wash your hands with soap immediately after reloading. Also, don’t eat or drink while you’re reloading. Ingesting hand residue into the body is NOT a good thing. You should also avoid breathing in dust—and it’s helpful if your work area is properly ventilated. Clean all flat surfaces—and you might want to avoid carpet in your work area, as it can hold a lot of residue.

Reloading can be an enjoyable and beneficial activity, whether you’re into it to save money, or to create a more effective round for your firearm. As long as you follow the rules of safely doing so.